Transportation and storage

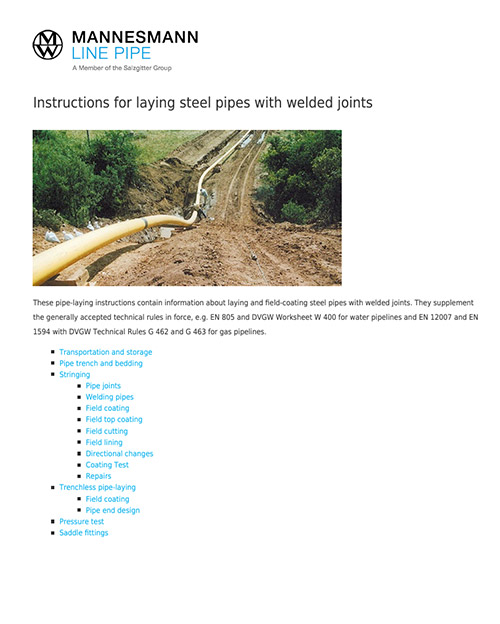

Pipeline components must be protected from damage. They should never be handled with sharp-edged lifting devices or steel ropes. Only equipment that ensures impact-free lifting and lowering may be used. Pipes must not be dropped or rolled.

Lifting tackle must be such that damage to the pipeline components and the coating is avoided (e.g. wide belts, padded ropes). Pipes fitted with handling caps can be lifted by the pipe ends with suitable hooks. The lifting tackle must be appropriately spaced to rule out impermissible sagging (and resultant deformation).

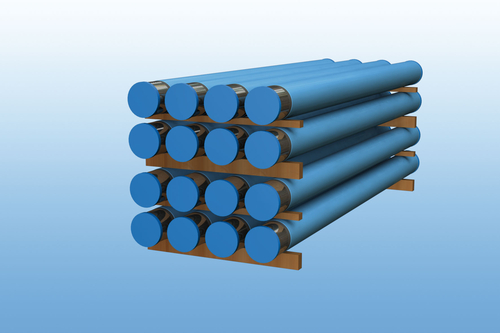

During transportation and storage, the pipeline components must be suitably separated and secured to prevent rolling, shifting, sagging and vibration. They should be stacked according to their lengths, e.g. on several planks or beams at least 100 mm in width, preferably using the wooden dunnage supplied with the pipes.

Loading areas must be free of burrs and sharp edges and, if necessary, must be padded to avoid damage. Pipeline components must be kept capped until they are laid so that they cannot be contaminated by soil, mud, dirty water, etc.

Supports and stack heights must comply with the applicable accident prevention regulations and rule out damage to the pipeline components. The load-bearing capacity and condition of the soil must be taken into account. The stack height should be between 2.0 and 3.5 meters.

Coated pipeline components with no other external protection such as an FCM coating must be protected from sunlight during storage periods of more than one year.